FLOCK

Spraying automatic machine

To be able to produce many thousands series of quality flocking, we use a five-axis spraying automatic machine for spraying of adhesive on the product. Thanks to it we are able to apply the adhesive in a well-defined layer and in a very short time on whichever 3D product.

Screenprinting automatic machine

Another possibility of the adhesive´s application is the screen printing. It is mainly used for flocking of accurate shapes on the surface - typically flock logo on textiles, paper or plastic. We have here an automatic machine with the high productivity of printing too.

Our references

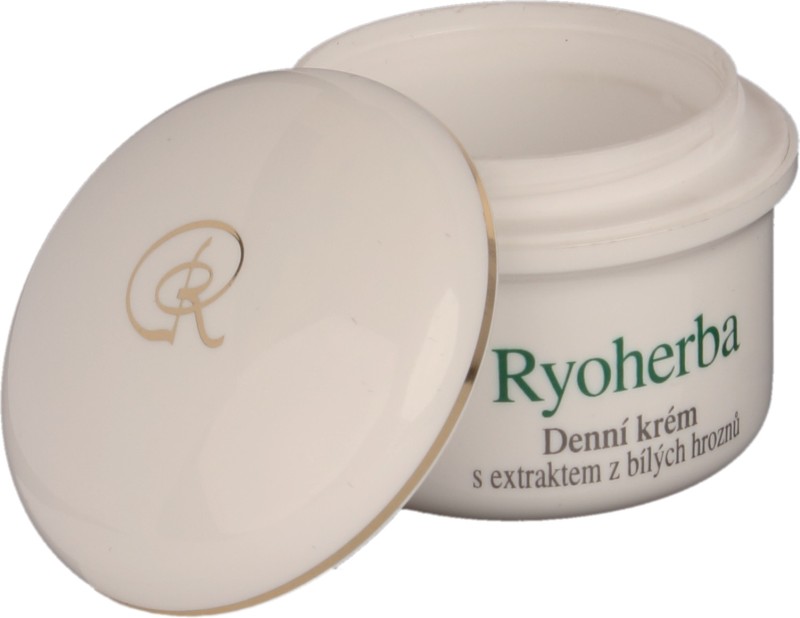

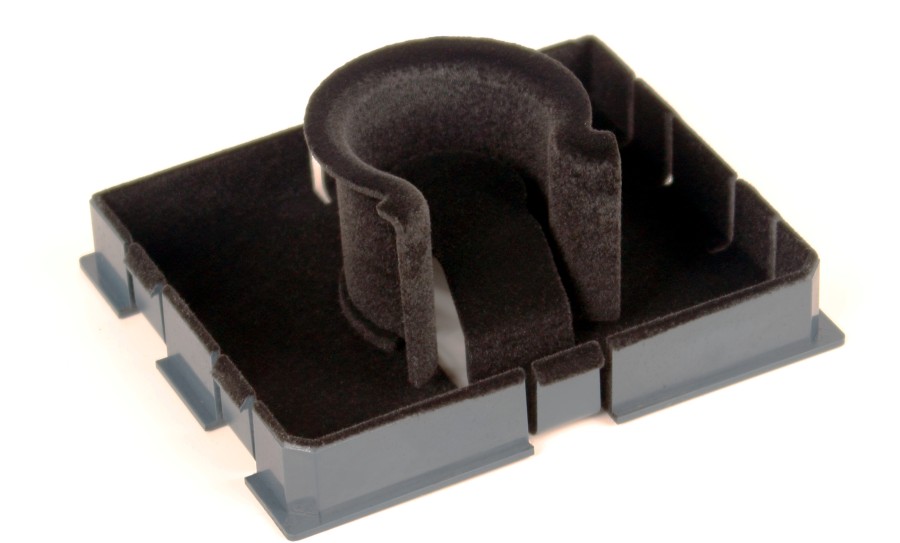

| Protection of fuser roller in the industrial copying maschines Xerox. Volume ca. 20.000 pcs/month. High demands on quality. |  |

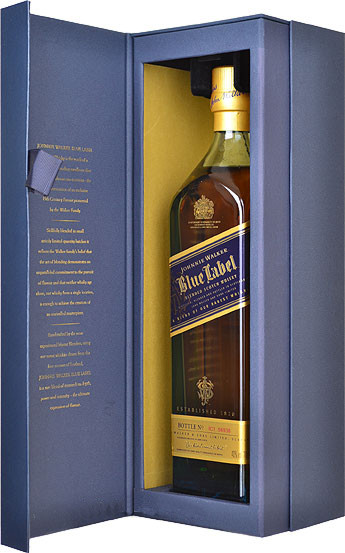

| Bottleneck´s holder at the luxury packaging of premium collection JohnnieWalker Blue Label. Volume 100.000 pcs |

| Foam pads into boxes to the luxury headphones AKG812 Pro. |  |

What is flocking and how does it work

Flocking is a technology that can create a suede surface on almost any product. The advantage is that we can achieve this fine velvet surface both on large surfaces as well as on complicated forms. The principle consists in applying of adhesive layer on the surface of the product and subsequent "shooting" of component hairs with the aid of very high voltages - typically 70kV. The high voltage causes that the hairs stand one by one vertically to the surface of the product and they create so a velvet surface.

Materials that can be flocked

It is possible to use the flock on practically whichever material. Commonly we use flock for all kinds of plastics, metals, wood, paper, glass, ceramics, hard and soft foams, carpets and textiles.

Resistance of the flocked surface

Resistance is always selected according to the type of application and it is determined by the adhesive used. By processing of calculation there is always consulted degree of required resistance and according to this we choose adhesive that suits for the application.

FLOCKING

The surface of the product is covered with the PES fibres. They create the luxury, suede appearance.

PAD PRINTING

Printing of the smaller surfaces with more complicated shapes than by screen printing. It allows to print very fine motives.

HOT STAMPING

The foil is hot-pressed into the plastic. It is suitable for silver, gold and other bold colors.

ENGRAVING

Material´s processing with the high-speed miller that is controlled with the 3D computer.

Jelinek s.r.o.

Svatopluka Cecha 492

Mnichovo Hradiste, 295 01

CZECH REPUBLIC

English speaking contact person at :

Mobile: +420 777 134 491

E-mail: info@jelineksro.cz

Working hours:

MO - FR: 7:00 - 15:30